Industry Talk

Regular Industry Development Updates, Opinions and Talking Points relating to Manufacturing, the Supply Chain and Logistics.Is reshoring real?

Manufacturers claim it’s harder to do business now than during the pandemic. This comes as 55 per cent of manufacturers report having adjusted their supply chain strategies for geopolitical reasons, while 54 per cent suggest they’d pay a premium for input if it meant it was localised, subsequently leaving supply less vulnerable to international trading friction. Here Thomas Lobert explains why these challenges are reshaping the landscape for manufacturers and what strategies they can employ to navigate this evolving business environment effectively…

Further research carried out by Censuswide, in a survey of 1,002 business leaders and financial leaders in the UK and US manufacturing industry, has also revealed how manufacturers are responding to the current complex landscape.

A further 58 per cent of manufacturers have started to reshore their supply chains, the process in which companies move production from overseas to the countries where goods are sold.

As a result, manufacturers expect to see several key benefits over the next two years. Cheaper products from reduced business costs, the ability to source products faster and receive higher quality products are all anticipated, but the arguably most critical factor is the opportunity to have enhanced reliability as well as security within their supply chains.

To become a beneficiary of these factors, a compliance strategy must supplement reshoring operations.

Two types of due diligence

Due diligence in business involves a thorough investigation and assessment of various factors before engaging in transactions or partnerships. Here, companies must conduct two dimensions of due diligence — jurisdictional and entity.

Jurisdictional due diligence involves comprehending the legal landscape of a country where a business operates, covering laws, tax regulations, trade policies and compliance requirements. Understanding these aspects, companies ensure adherence to regulations and maintain compliance.

As for the latter, entity level due diligence focuses on assessing the integrity and reputation of the specific entity or company involved in the transaction. This examines financial health, business practices, ownership structure and any past legal issues or sanctions. Put simply, conducting entity level due diligence ensures companies can assess the reliability and trustworthiness of their potential partners or counterparts.

However, companies must also consider geopolitical factors, like uprisings, social unrest and corruption, even if they comply with legal requirements. These factors can significantly impact business operations, with geopolitical volatility providing substantial risk for companies that need to be mitigated for.

Supplier selection

Transitioning production back home can present specific compliance challenges. Despite the familiarity of the home jurisdiction, companies cannot overlook due diligence on partners and suppliers. Even in domestic operations, there could be bad actors or non-compliant entities involved.

And while selecting local vendors may seem less complex, they can also be subject to restrictions, sanctions or debarment if found violating laws. Compliance checks should, therefore, verify that vendors meet legal and ethical standards, ensuring that the products or services procured uphold quality and integrity.

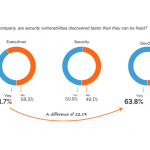

Such need for compliance comes as only 33 per cent of European and 24 per cent of U.S. CEOs are confident in their supply chain resiliency. That’s according to the 2022 ISG Smart Manufacturing Survey, which demonstrates manufacturers concerns about their supply chain.

But, as explained, reshoring operations still present significant challenges that require a robust compliance strategy. Here, our Visual Compliance solution offers a centralised platform for conducting streamlined due diligence activities during the reshoring process.

By integrating government published lists and custom-built specialty lists from reputable research firms, the software tool ensures comprehensive screening of local partners and suppliers.

At a time when manufacturers find it difficult to do business, this unified approach allows companies to efficiently assess potential risks and ensure adherence to regulatory requirements, facilitating a safe and seamless transition to local operations.

To find out more about Descartes denied party screening software, visit VisualCompliance.com.